With the rapid development of science and technology, we have witnessed many breakthroughs in materials science, among which electron beam curing (EBC) technology is one of the best. This technology not only brings innovations in material processing methods, but also shows its unique charm in the field of decorative panels.

In short, electron beam curing technology uses high-energy radiation from electron beams to trigger chemical reactions, so that the materials reach a cured state in a short time. In the production process of decorative panels, EBC technology precisely acts on the coating material through high-energy electron beams generated by electron accelerators. The energy of these electron beams is enough to break the chemical bonds in the coating, causing the molecules in the coating to polymerize and form a strong and stable coating structure.

Compared with traditional thermal curing or light curing technology, EBC technology has significant advantages. Electron beams have stronger penetration and can penetrate deep into the coating to achieve a more uniform curing effect. EBC technology has an extremely fast curing speed, which greatly shortens the production cycle. EBC technology can also be cured at low temperatures, avoiding the influence of high temperature on material properties.

The secret of EBC technology lies in its unique energy transfer method and reaction mechanism. As a high-energy particle beam, electron beams have extremely high energy density and penetration. When the electron beam hits the coating material, it transfers the energy it carries to the molecules in the coating, allowing them to obtain enough energy for chemical reactions. This energy transfer method is not only efficient, but also highly selective, and can act precisely on the area that needs to be cured.

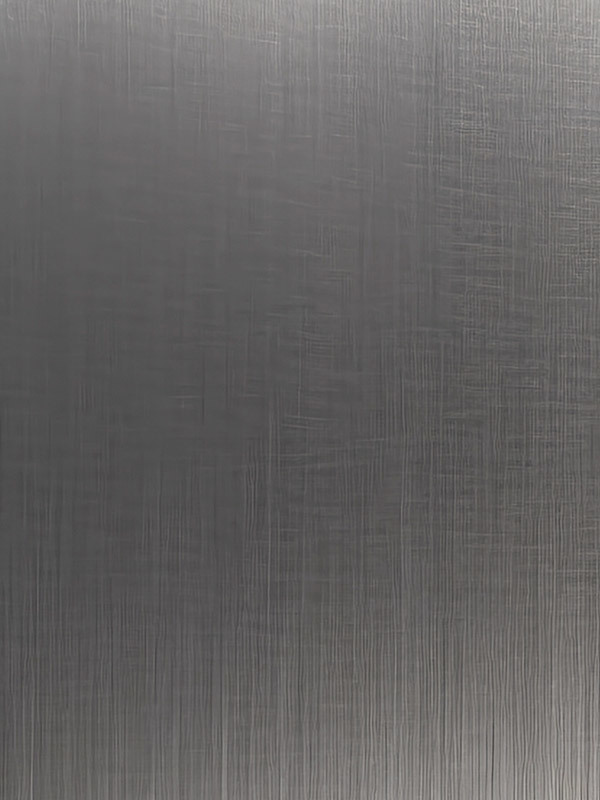

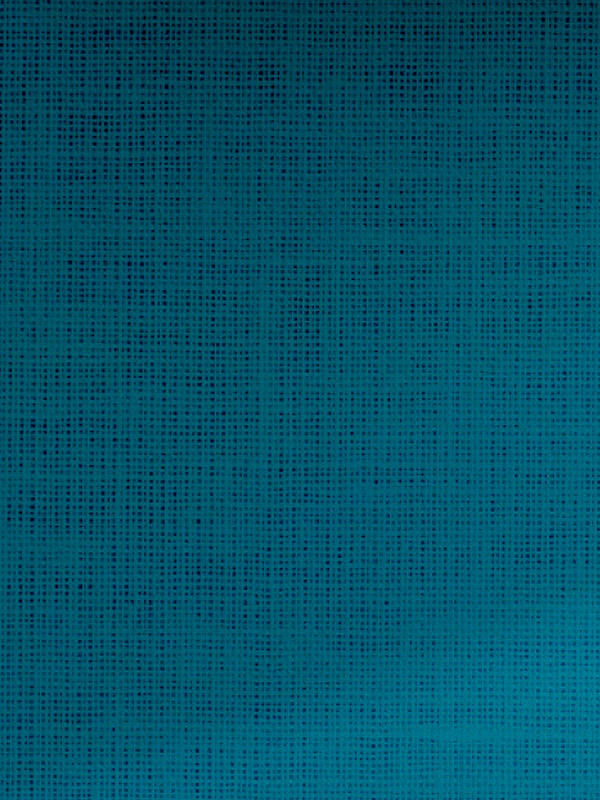

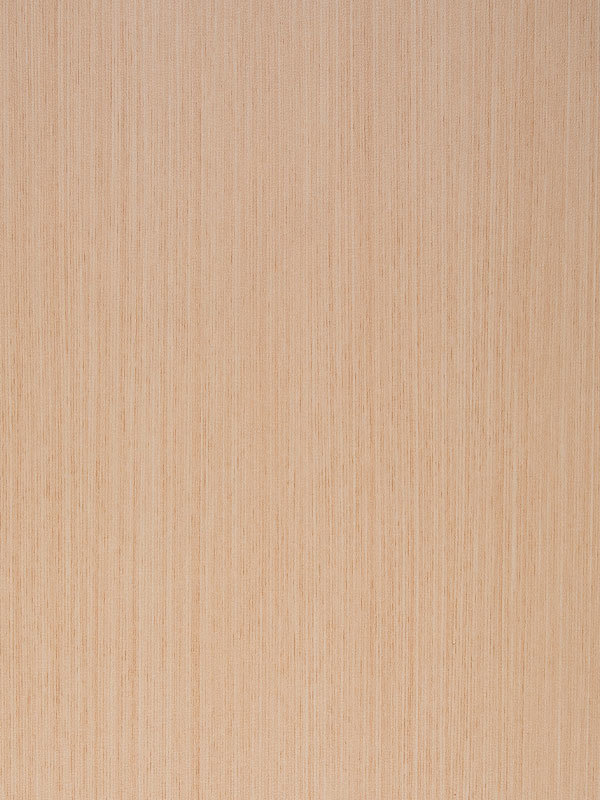

In the reaction mechanism of EBC technology, after the molecules in the coating obtain energy, polymerization reactions will occur to form new chemical bonds. These newly formed chemical bonds not only enhance the strength and stability of the coating, but also give the coating a series of properties, such as wear resistance, scratch resistance, and weather resistance. The improvement of these properties makes EBC decorative panels perform well in practical applications and are widely favored.

As a new type of environmentally friendly material, EBC decorative panels have broad application prospects. EBC decorative panels have performance and beautiful appearance, which can meet people's pursuit of high-quality life. The production process of EBC decorative panels is environmentally friendly and pollution-free, which conforms to the concept of sustainable development. EBC decorative panels also have a wide range of applications, such as home decoration, building exterior walls, and automotive interiors.

With the continuous advancement of science and technology and the popularization of environmental protection concepts, the application prospects of EBC decorative panels will be broader. In the future, EBC decorative panels are expected to play a greater role in smart homes, green buildings and other fields, creating a better living space for people.

Electron beam curing (EBC) technology has shown great potential in the field of decorative panels with its unique principle and performance. By deeply understanding the mystery and application prospects of EBC technology, we can better understand the important position of this technology in modern materials science. Let us look forward to EBC decorative panels bringing us more surprises and possibilities in the future.

English

English 中文简体

中文简体 русский

русский Español

Español