In the field of modern architectural decoration and material science, High Pressure Laminate (HPL), or high pressure laminate, has become a shining star in the market with its performance and wide application prospects.

HPL, the full name of which is High Pressure Laminate, is a decorative material made by high pressure and high temperature treatment. Its manufacturing process involves impregnating cellulose paper in resin and then curing it under high temperature and high pressure. This process not only gives HPL physical properties, but also makes its surface colorful and diverse in pattern, which can meet the needs of different decorative styles.

Unique properties of HPL

Abrasion resistance: HPL has a high surface hardness and can effectively resist scratches and impacts. It is suitable for use in places with high traffic density and frequent use. This feature makes HPL an ideal choice for decoration in public places.

Fire resistance: HPL has good flame retardant properties and will not burn easily even when exposed to fire sources, which greatly improves the safety of buildings. This feature is particularly important in places with high fire protection requirements, such as laboratories and hospitals.

Waterproof: Due to the addition of waterproof resin during the production process, HPL has good waterproof performance and is suitable for use in environments with high humidity, such as bathrooms and kitchens.

Corrosion resistance: HPL has good corrosion resistance to chemicals such as acids, alkalis, and salts, and is suitable for use in special environments such as chemical and medical treatment.

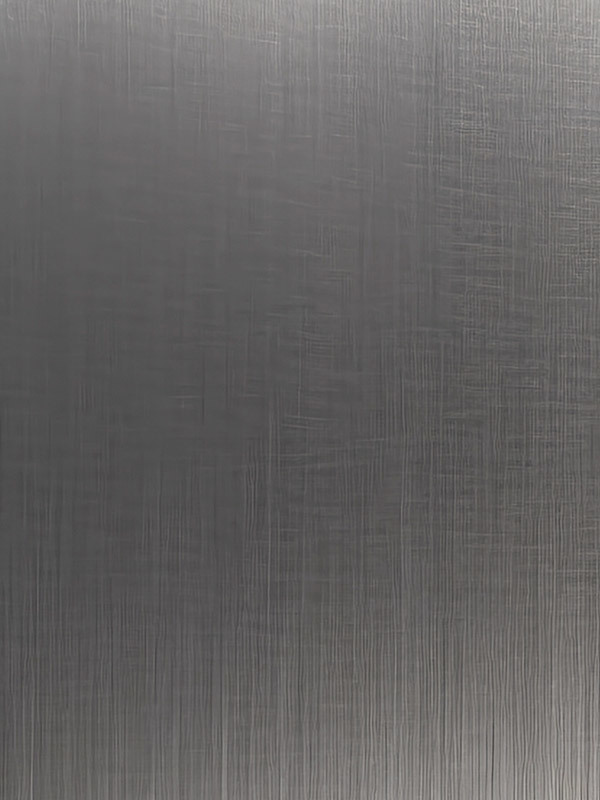

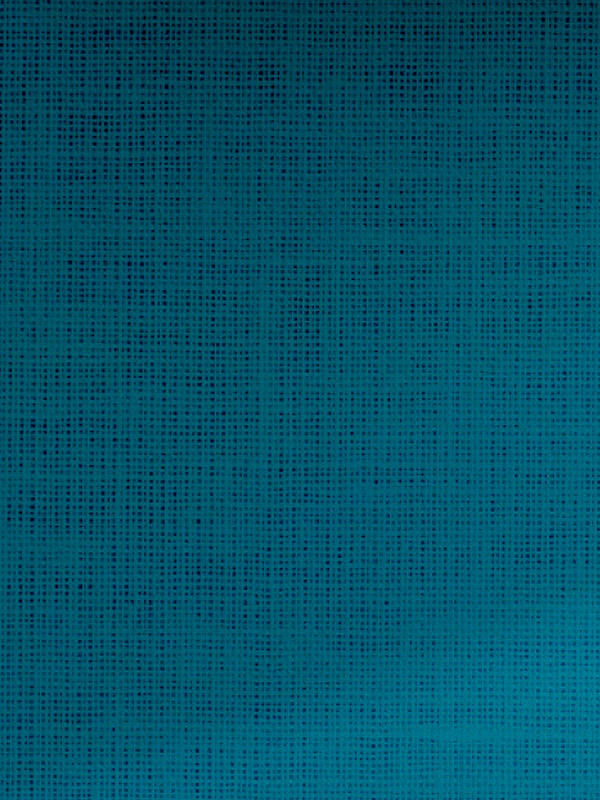

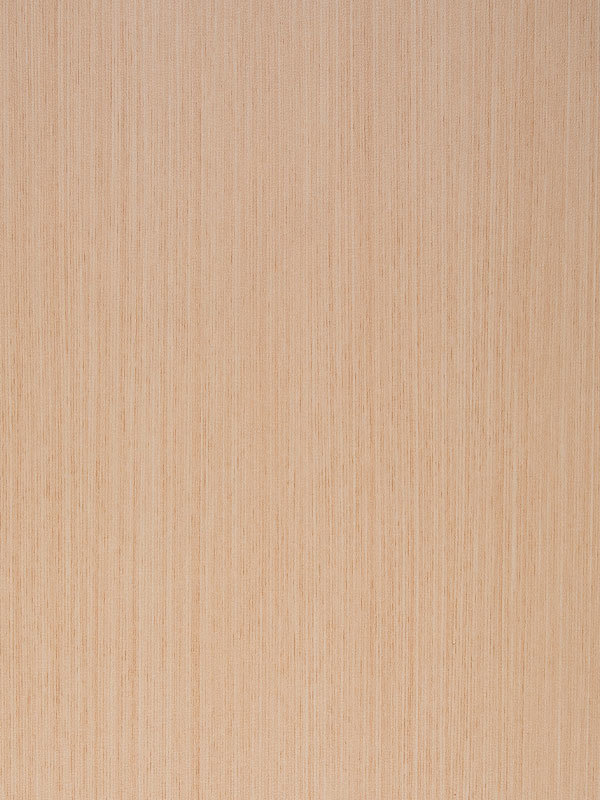

Decorative: The surface of HPL is rich in color and can simulate various natural textures, such as wood grain and stone grain, providing more choices for architectural decoration.

With the above performance, HPL has been widely used in the architectural decoration industry. It is widely used in the decoration of walls, floors, ceilings, and furniture in public places such as offices, shopping malls, restaurants, schools, and hospitals. HPL is also used in the interior decoration of ships, trains, airplanes and other means of transportation to provide passengers with a comfortable and beautiful riding environment.

With the rapid development of the construction and furniture industries, the market demand for HPL continues to grow. In the future, HPL will develop in a more environmentally friendly and multifunctional direction. On the one hand, with the increasingly stringent environmental regulations, the production of HPL will pay more attention to the selection of environmentally friendly materials and energy conservation and emission reduction in the production process. On the other hand, in order to meet the needs of different application fields, HPL will develop more products with special functions, such as antibacterial and fireproof, to broaden its application scope.

As design trends change, HPL will provide more innovative patterns and texture options to adapt to different decoration styles and design needs. This will enable HPL to continue to play an important role in the fields of architectural decoration and material science, creating a better and more comfortable environment for people's lives and work.

English

English 中文简体

中文简体 русский

русский Español

Español